|

Coldwater Machine Co. has introduced the StaticLube™ electrostatic lubrication system. Available for both sheet metal and coil stock, the system decreases lubricant consumption for metal stampers and fabricators by up to 95 percent as compared to other systems, says the company. It delivers 100 percent efficiency with zero waste, overspray, VOCs, odor, and disposal costs, the manufacturer reports.

With the system’s electrostatic atomization venturi system, the lubricant is negatively charged and thus attracted to the neutral, grounded material. This distributes millions of micron-sized particles of either oil-based or solid dry-film lubricants evenly across the surface of sheets or coils of metal, producing a uniformly lubricated surface.

System speed can be adjusted from 1 to 1,000 FPM. Sheet thickness is 0.005 to 0.375 in., and precision coating thickness capability is 1 to 1,000 mg/sq. ft. It is available in several standard models that will accommodate ferrous and nonferrous coil and sheet stock from 1 to 75 in. wide.

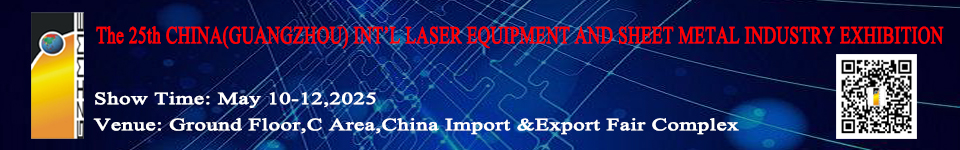

中国最大钣金展-锻压展-2016第十七届广州国际钣金、锻压工业展览会-巨浪展览-

-The

17th China(Guangzhou)Int’l

Sheetmetal machinery, Forging, Stamping and Setting Equipment Exhibition

|