|

Coldwater Machine Co. has announced its ability to design and build laser ablation systems. Based on company standards that are adapted for specific requirements, the systems can be designed to stand alone or to be integrated into any manufacturing process that requires cleaning of parts before another operation.

The laser creates a clean, smooth surface by eliminating burrs and nicks without increasing surface roughness.

In its most recent application, the company integrated a 3- by 3-ft. laser ablation station around existing automation within a laser welding cell. In this instance, the components for cleaning travel on a conveyor into a Class 1 laser enclosure with glass tinted for viewing of laser processes. The door then comes down to enclose the part and shield the light emitted from the 100-W laser. Situated on a servo-driven powered slide unit, the part is raised up and rotated 360 degrees to ensure that dust, oil, coolant, and debris are removed from all sides.

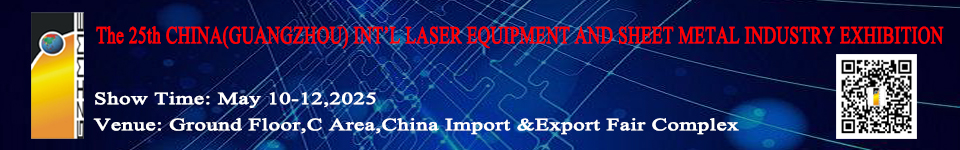

钣金展-激光设备展-2019年广州国际激光设备及钣金工业展

-2019 China(Guangzhou) Int’l Laser Equipment and Sheet Metal Industry Exhibition

-Sheet metal exhibition, Sheet metal expo, 2019 Sheet metal exhibition, 2019 Sheet metal expo, China Sheet metal exhibition, China Sheet metal expo, Laser Equipment exhibition, Laser Equipment expo, 2019 Laser Equipment exhibition, 2019 Laser Equipment expo, Laser exhibition, Laser expo

|