|

|

| |

|

|

Cahya Mata associate manganese alloy smelting plant to reach full output in Q3- The 18th China£¨Guangzhou£©Int¡¯l Sheet metal machinery,Forging, Stamping and Setting Equipment Exhibition

5/4/2017 Sheetmetal machinery, Forging, Stamping expo |

--------------------------------------------------------------------------------------------------------------- |

|

The Star reported that Cahya Mata Sarawak Bhd is expecting its associate company OM Materials (Sarawak) Sdn Bhd''s ferrosilicon and manganese alloy smelting plant to achieve full production by the third quarter of this year. Mr Datuk Richard Curtis Group managing director said the recovery in demand for the commodities has enabled the smelting plant in Samalaju Industrial Park, Bintulu to go on full-scale production. He is also optimistic that OM Materials would be able to to churn in profits this year when all the 16 furnaces eight ferrosilicon and eight manganese are in operation.

Mr Curtis told StarBiz recently that "This will give the plant maximum operational efficiency.¡± The two-phase development for OM Materials smelting plant is estimated at USD 458 million. The OM Material''s phase one smelting facility, which was completed in 2015, started with the production of ferrosilicon.

However, the global ferroalloys market during the year had experienced a sharp slowdown due to excessive production and inventory.

This prompted the plant to shut down its two furnaces to facilitate reconfiguration of the product-mix, adding manganese alloys to its production capability.

Mr Curtis said that "The reconfiguration of the product-mix allows the company to package different types and grades of alloys to end-users and distributors in markets such as Japan, Taiwan and South-East Asia.¡±

By realigning its business and diversifying its product offerings, he said this helped the company to reduce reliance on the weakened ferrosilicon market and position itself to benefit from the stronger market that began to emerge in 2016.

It also, said Mr Curtis, enabled the company to fill the regional manganese alloy supply gap. Unlike the ferrosilicon market, which was reported to be affected by dumping activities from Chinese manufacturers, the global manganese market is not influenced by China.

By end-2016, seven ferrosilicon furnaces and one manganese furnace were in operation. The year saw the plant''s ferrosilicon production output totalling 126,261tonnes, exceeding the nameplate daily production capacity of 55 tonnes. The single manganese furnace achieved a production volume of 876 tonnes of siliconmanganese during the short period of operation.

The second modified furnace completed its hot commissioning in January, with the first tap of high carbon ferromanganese.

The number of modified furnaces is expected to be increased to six by next month when OM Sarawak will produce a wide range of products, such as refined ferrosilicon like low aluminium ferrosilicon and low calcium ferrosilicon, and high-grade siliconmanganese, according to OM Holdings Ltd (OMH), which has a 75% stake in OM Materials, in a recent update. CMS owns the remaining 25% equity in the joint-venture (JV) company.

-

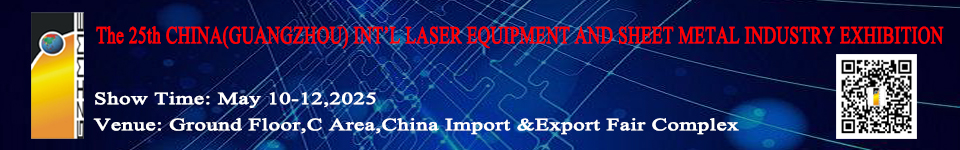

The 18th China£¨Guangzhou£©Int¡¯l

Sheet metal machinery,Forging, Stamping and Setting Equipment Exhibition

|

|

|

|

|