|

|

| |

|

|

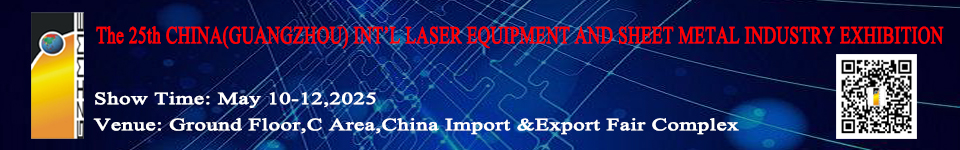

Sheet Metal Forming- The 18th China(Guangzhou)Int’l Sheet metal machinery,Forging, Stamping and Setting Equipment Exhibition

4/12/2017 -sheet metal expo |

--------------------------------------------------------------------------------------------------------------- |

|

Bending is a metal forming process in which a force is applied to a piece of sheet metal, causing it to bend at an angle and form the desired shape. A bending operation causes deformation along one axis, but a sequence of several different operations can be performed to create a complex part. Bent parts can be quite small, such as a bracket, or up to 20 feet in length, such as a large enclosure or chassis. A bend can be characterized by several different parameters, shown in the image below.

The act of bending results in both tension and compression in the sheet metal. The outside portion of the sheet will undergo tension and stretch to a greater length, while the inside portion experiences compression and shortens. The neutral axis is the boundary line inside the sheet metal, along which no tension or compression forces are present. As a result, the length of this axis remains constant. The changes in length to the outside and inside surfaces can be related to the original flat length by two parameters, the bend allowance and bend deduction,

中国最大钣金展-锻压展-2017第十八届广州国际钣金、锻压工业展览会-巨浪展览- The 18th China(Guangzhou)Int’l Sheet metal machinery,Forging, Stamping and Setting Equipment Exhibition

|

|

|

|

|