|

Technavio has announced the top five leading vendors in their recent global metal fabrication equipment market report until 2020. This research report also lists seven other prominent vendors that are expected to impact the market during the forecast period.

In 2015, the global metal fabrication equipment market generated around USD 68 billion and this is predicted to exceed USD 94 billion in 2020.

Metal fabrication is vastly used in the manufacturing sector but in due course, the demand-supply scenario for the metal fabrication market in major industries such as aerospace and defense will gain traction as these industries extensively use fabricated metal sheets. The automotive industry is another major end-user of fabricated metal sheet. Stamping processes, which includes metal bending, will support the growth of the metal fabrication equipment market in sync with rising automotive.

The evolution of advanced machine tool technologies like high-speed fiber laser cuttingtechnology is impacting the manufacturing industry as well as the overall metal fabrication equipment market. The ability of this technology of working at a much faster rate than conventional machines is pushing OEMs to manufacture faster press brakes to adapt to the speed of change in fabricating processes.

Competitive vendor landscape

The global metal fabricating equipment market is dominated by the major vendors at present. But these vendors are encountering strong competition from several regional and local vendors who have started manufacturing customized, energy-efficient equipment that are available at lower prices than those offered by their international counterparts. And with vendors ushering in products with new features and technologies, the competition will become more hostile.

In the earlier days, market vendors concentrated on improving the setup time of press brakes, and most developments were directed toward the same. However, at present, they are adapting to changing market dynamics in terms of required cost-effectiveness. A universal shift towards automation and other advanced technologies is observed among market vendors as they try to reduce the cost for smaller lot sizes without compromising on the quality of products. ¡°The market has considerably shifted from manufacture-led production and is more inclined toward demand-led strategies. Also, with the relentless fluctuations in global economic growth and the consequent decline in the demand for products, OEMs and suppliers are losing interest in maintaining large product inventories and are focusing on just-in-time demand,¡± says Gaurav Mohindru, a lead analyst at Technavio for research on tools and components.

Top five metal fabrication equipment market vendors

Colfax

The company offers various solutions for the global metal fabrication equipment market through its ESAB brand. ESAB produces equipment and filler metals for various welding and cutting applications. It provides solutions for various industries, including energy, machinery, fabrication, construction, power generation, shipbuilding, transportation and others. ESAB has 26 manufacturing plants in four continents, and sales and support representatives in 80 countries.

DMG Mori

DMG Mori has an established presence in the metal fabrication equipment market with its range of offerings. The company continues to develop and promote the software solution CELOS, which is a control and technology-independent system that supports interaction between machine and its operators. Its new app was introduced in April 2015.

DMTG

DMTG manufactures and sells products such as flexible production lines, bridge type machining centers, CNC milling and boring centers, machining centers, CNC milling machines, CNC lathes, conventional lathes, and drilling machines. These products are offered in a range of series to various industries such as automation, automobile, shipbuilding, engine, and general engineering.

TRUMPF

TRUMPF offers various bending solutions under the global metal fabrication equipment market. TruBend 3000 series is one of the solutions provided by the company. This solution allows earning more profits, even at lower utilization rates. It helps customers to enter the field of TRUMPF bending technology and also expand the existing machinery. Some of its principal features include cost-efficiency (even when operated at low capacity), high productivity, high part accuracy, simple operation (well thought-through control), and others.

-

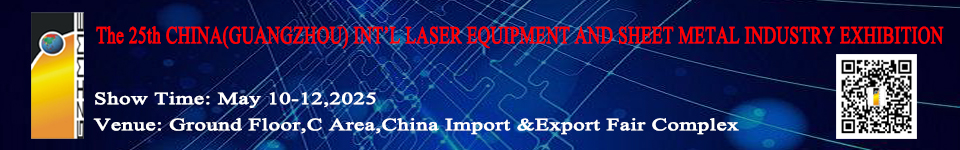

The 18th China£¨Guangzhou£©Int¡¯l

Sheet metal machinery,Forging, Stamping and Setting Equipment Exhibition

|